INTRODUCTION

After several decades with relatively few innovations, recent investment into planting technologies by equipment manufacturers has resulted in giant leaps forward in both high- and low-tech solutions for improved planting. Equipment manufacturers have developed systems that are faster and produce more uniform emergence across varied conditions. While these technologies may not consistently improve soybean production, they should be considered when the same planters are being used across commodities, where greater yield responses may be observed. Please note that mention of any technology in this document does not imply endorsement of one technology product versus another nor discrimination against any product not mentioned by the authors or universities.

New planting technologies can provide these additional benefits to crop production:

- Increased planting efficiency. As farm size continues to increase concurrently with labor shortages, farmers are interested in increasing planting speed to improve planting efficiency. Early attempts at increasing planting speed were focused on simply expanding planter size. However, increased ground speed can provide the same net result of increased planting efficiency, so significant efforts have been made to allow planters to precisely place seeds even at high operating speeds.

- Uniform and precise seed placement. Soybean seed requires warm, moist soil for rapid germination and emergence. Good seed-to-soil contact is an absolute requirement. Planting the seed into moisture and firming the soil around the seed to maintain the appropriate environment is essential. Planting too deep can delay or impede emergence, and planting too shallow can allow the soil to dry prior to emergence leading to the potential seed death. Uniformity of depth is important for timely and uniform emergence.

- Increased soil tilth and warming. Appropriate row cleaners and coulters can provide a much-improved seedbed directly around the seed and improve seed-to-soil contact. The exposed soil directly above the seed can warm faster than covered soil, facilitating more rapid and uniform seedling emergence.

- Reduced seed costs. A significant economic benefit for many planter technologies is the result of reduced seed costs. Precise placement of individual seeds allows for a greater emergence percentage and allows farmers to reduce seeding rates.

- On-the-go adaptation to changing soil conditions. Soil types and physical properties are highly variable within and between fields. Planters that can be adjusted automatically and in real-time allow farmers to plant each seed into an ideal environment across every acre.

- Environmental benefits. Precise placement of fertilizers, biologicals, and pesticides without overlaps allows for reductions in total quantities of products required and off-target movement.

Seed Delivery

SEED SINGULATION

Seed singulation refers to the ability of a planter to drop each seed at the desired spacing within the row. Singulation errors can be either skips, where a seed is missing within a row, or multiples, where two or more seeds are placed at the same location.

In corn, seed singulation can significantly impact yield (Russell et al., 2021). Soybeans are more tolerant to a wide range of planting densities, and generally, seed singulation does not impact soybean yield (Ess et al., 2005), especially at higher seeding rates (Mourtzinis et al., 2021).

When improved seed singulation increases yield, it tends to be in rows narrower than 15 inches, especially in late-planting or double-crop scenarios (Holshouser et al., 2006) or at suboptimal seeding rates (Mourtzinis et al., 2021).

HIGH-SPEED PLANTING

Most ground-driven mechanical soybean planters are operated at speeds between 3 and 6 mph. Planters with some modified components can be operated at speeds higher than 8 mph, sometimes as fast as 12 mph, while maintaining the target seeding rate and singulation. Many technologies should be considered for effective planting at higher speeds, including downforce, improved closing wheels, and seed delivery tubes with belts or bristles that improve seed singulation and reduce the movement of seeds within the seed trench (Figure 1).

High-speed planting can increase planter productivity and allows more area to be planted in a given day with a single machine and operator (Darr and Bergman, 2020). Belt-type seed delivery tubes are more sensitive than bristle-type seed delivery tubes and can get plugged when planting large-seeded soybean varieties, especially at speeds above 7 mph (Darr and Bergman, 2020). When planting at high speeds, the use of active downforce systems may become increasingly important for seed depth accuracy.

Since high-speed planting can require additional costly technology investments, generally, the return on investment may be greater for farms that have many large fields or very narrow time frames with suitable planting conditions. Farms with many small fields with frequent turns are less likely to see an improved return on investment with high-speed planting.

VARIABLE RATE SEEDING

Seed is one of the costliest inputs for soybean farmers. Variable rate seed meters are a technology that allows the planter to automatically change seeding rates within a field based on a prescription map. Some variable-rate planters also have two separate hoppers of seed, which allows for multivariety planting within the same planter pass.

Variable rate seeding (VRS) aims to increase profit by optimizing the seed rate for each individual management zone, instead of selecting one average seeding rate for the whole field. Generally, the optimum soybean seeding rate is lower where yield potential is higher (Carciochi et al., 2019). Different field properties can be used to delineate management zones and set seeding rates, and common choices include past yield maps, soil map units, soil fertility from grid soil sampling, soil organic matter or soil electrical conductivity, elevation, or a combination of factors. Delineating management zones based on yield maps alone can lead to unstable management zone boundaries since patterns in yield maps can vary significantly between years due to differences in weather conditions (Bunselmeyer and Lauer, 2015; Maestrini and Basso, 2018).

Potential returns for variable rate seeding differ between fields. Fields with higher variability, such as fields that have multiple soil types, significant elevation changes, or irrigation practices are more likely to benefit from variable rate seeding. Additionally, farms that have already invested in farm data management tools that can process geospatial data will require fewer additional investments, which can increase the return on investment (ROI) associated with VRS technology.

CAVEATS TO THE TECHNOLOGY

At the time of the writing of this document, data management and data interpretation is still a large barrier to developing accurate variable rate prescriptions. In an Ohio and Michigan study, only 40% of the time farmers selected a seeding rate that was within the top 10% of the agronomic optimum for a given management zone. The remaining 60% of the time, the seeding rate was less than 90% of the agronomic optimum (Hamman et al., 2021). Additionally, variable rate seeding will only pay in fields that have significant variability between management zones.

CITATIONS:

Bunselmeyer, H.A., & Lauer, J.G. Using corn and soybean yield history to predict subfield yield response. Agronomy Journal. 2015. 107, 558– 562. https://doi.org/10.2134/agronj14.0261.

Carciochi, W.D., Schwalbert, R., Andrade, F.H., Corassa, G.M., Carter, P., Gaspar, A.P., Schmidt, J., & Ciampitti, I.A. Soybean seed yield response to plant density. Agronomy Journal. 2019. 111, 1– 10. https://doi.org/10.2134/agronj2018.10.0635.

Darr, M. & Bergman, R. High Speed Planting Technology. Iowa State University Extension and Outreach. 2020. https://crops.extension.iastate.edu/cropnews/2020/03/high-speed-planting-technology.

Drewry, J.L., Luck, B.D., and Arriaga, F.J. Impact of planter closing wheels on corn emergence in no-till systems. Applied Engineering in Agriculture. 2020. 36(5), 727-732. https://doi.org/10.13031/aea.13957.

Ess, D. R., Hawkins, S.E., Young, J.C., & Christmas, E.P. Evaluation of the performance of a belt metering system for soybeans planted with a grain drill. Applied Engineering in Agriculture. 2005. 21(6):956-969. https://elibrary.asabe.org/pdfviewer.asp?param1=s:/8y9u8/q8qu/tq9q/5tv/J/quqzIGGL/IH/M/52LLKP.5tv&m2=N/IO/ IGII&m3=HIO.IIN.H.HL&m4=20028.

Planter Downforce

WHAT IS IT?

Planter downforce is an add-on planter technology that enables equipment operators to add (or subtract, in the case of active systems) additional force to the row unit which in turn maximizes ground contact and maintains a more uniform seeding depth. Active downforce systems (such as hydraulic and pneumatic) keep opening disc depth constant across the field, as opposed to static downforce systems (such as manual springs or some pneumatic airbag systems) which maintain constant pressure on the row unit itself but do not add or subtract downforce on the go.

Ultimately, planter downforce allows adjustments to be made to the planter so that the disc openers can overcome the resistance of the soil surface, increasing seed-to-soil contact and planter performance. The objective of utilizing planter downforce is to ensure that targeted seed depth is achieved across the field accounting for soil and residue variability, resulting in uniform emergence.

WHAT IS AVAILABLE?

Planter downforce can be categorized into three systems: manual springs, pneumatic airbags, or hydraulic (Figures 2-4). Each of these systems provides the planter operator with some control over increasing downward force to the row unit. However, some pneumatic systems and most hydraulic systems allow for force adjustments to be made as well as the option of row-unit lifting or up force. Most popular planter manufacturers in the United States provide manual springs on planters as standard equipment. Typically, if downforce is to be upgraded beyond manual springs, aftermarket technology will need to be purchased.

WHERE IS THIS TECHNOLOGY BEST SUITED?

Planter downforce is typically best suited in cropping systems where adverse planting conditions are frequent and poor planter ground contact is often observed. These conditions include no-till planting, planting into crop residues or cover crops, or into situations where soils are not smooth. Additionally, downforce technology could assist with maintaining appropriate seed depth when high-speed planting (> 8mph).

CAVEATS TO THE TECHNOLOGY

As with many new precision technologies, truly understanding the appropriate setup, operation, and return on investment are all often hard to define. As production systems become more sitespecific, determining uniform recommendations across regions, commodities, or technologies is nearly impossible. While downforce technology has shown promise among major row crops with stand establishment and yield benefits, understanding the appropriate applications for use are not clearly defined.

DOWNFORCE SOYBEAN RESEARCH

In theory, where the seed is placed at a uniform depth, uniform emergence will occur. In corn, research has demonstrated that uniform emergence can result in significant yield increases, however, this may not be the case in soybean (Carter et al., 1989; Nafziger et al., 1991; Lawles et al., 2012). Downforce technology has been extensively evaluated in corn production throughout the United States, where yield benefits are observed and emergence is uniform. In soybean, evaluations of downforce have been limited. Soignier et al. (2022) evaluated soybean response to varying downforce rates among tillage types and gauge wheel width in South Carolina. This research resulted in differences in soybean emergence as a function of downforce rate, though significant yield differences among downforce rates were not observed.

CITATIONS:

Carter, P., Nafziger, E., & Lauer, J. Uneven emergence in corn. North Central Regional Extension Pub. 1989. No. 344.

Soignier, T.S., Plumblee, M.T., Greene, J.K., Mueller, J.D., & Kirk, K.R. The evaluation of planter downforce on emergence and grain yield in soybean. Crop, Forage, Turfgrass Management. 2022. 8(2), e20186. https://doi.org/10.1002/cft2.20186.

Nafgizer, E., Carter, P., Graham, E. Response of Corn to Uneven Emergence. Crop Sci. 31:811-815. 1991.

Lawles, K., Raun, W., Desta, K., Freeman, K. Effect of

Delayed Emergence on Corn Grain Yeilds. Journal of

Plant Nutrition. 35:3, 480-496. 2012.

In-furrow Application Technologies

Most in-furrow precision applications relate to improving the placement of liquid products, specifically starter fertilizers. Although these systems may be applied to nematicide, fungicide, biological, and other in-furrow applications, this article will focus on the principal application of precision in-furrow technologies: fertilizer/liquid placement.

WHAT IS AVAILABLE?

Several technology manufacturers have developed solutions for increased control over rate, placement, and monitoring of liquid and granular in-furrow applications. With these technologies, farmers have the ability to apply products to different areas of the furrow and to or around the seed. A few unique examples of these technologies are described below. FurrowJet is a technology available from Precision Planting that injects three bands of liquid product(s) along the seed trench (Figure 5). One band is placed with the seed, and two bands are placed in the sidewall about 3/4-inch away from the seed. Placing two-thirds of the fertilizer to the sides of the seed is meant to reduce the chances of seedling burn from high salt concentrations placed directly on the seed. Since phosphorus (P) is not mobile in soil, the idea is to place P starter fertilizer near the seed for easy access by roots. The system can utilize up to three different products, so it is possible to apply nematicide in-furrow with the seed, P to one side, and nitrogen (N) to the other side. The FurrowJet system also comes with a seed firmer to keep seed in place and improve seed-to-soil contact.

SelectShot, by CapstanAg, places liquid products on a ‘per seed’ basis (Figure 6). The technology can place a dose of a product either before the seed or on top of the seed. In soybean systems, where seeds are closely spaced in the furrow, this technology is likely to resemble more traditional, single-stream in-furrow delivery. But in systems where seed rates are lower, such as corn or cotton, this technology may find an increased return on investment, particularly with expensive products, such as in-furrow nematicides.

The 360 Dash system from AgXcel is operationally similar to the SelectShot in that it pulses a liquid product on the seed. The “dash” of fertilizer is placed over 2 to 3 inches on top of the seed. Again, under high seeding rates, this technology may have a limited return on investment compared to single-stream technologies. The technology claims accuracy at speeds of 4 to 10 mph and 2.5 to 15 gallons per acre.

Technologies for granular in-furrow products have been developed to allow for on-the-go rate control through electric or hydraulic drives. These technologies can aid with the in-field placement of costly granular products through variable rate or on/ off prescriptions. One example of this technology is SmartBox+ from AMVAC Chemical Corporation which meters granular fertilizer using an electronically controlled auger to each row.

CAVEATS TO THE TECHNOLOGY

Placing fertilizer in-furrow with the seed can result in seedling burn due to high salting effects immediately surrounding the seed upon germination and emergence. Safe rates of in-furrow fertilizers vary between products, soil types, and moisture conditions. P fertilizer does not significantly contribute to salt risk, but N, potassium (K), and sulfur (S) can cause increased salt injury. Compared to many crops, soybean seedlings are more sensitive to salts. A rate that is safe for corn may be too high for soybean in the same field conditions.

In addition to salt injury, which can be caused by many fertilizers, N fertilizer can also damage seedlings through ammonium toxicity. Ammonium is especially toxic to seedlings when it is concentrated in the furrow.

In coarse-textured soils of the Southeast US, the technology may find greater utility in the precise application of in-furrow nematicides, where products are expensive compared to in-furrow fertilizer. Fungicide applied with fertilizers in-furrow can also increase yields in some high-disease environments across the Midsouth, Midwest, and Ontario, although yield increases tend to be small on average (~1.6 bu/acre).

CITATIONS:

Nkebiwe, P.M., Weinmann, M., Bar-Tal, A., & Müller, T. Fertilizer placement to improve crop nutrient acquisition and yield: A review and meta-analysis. Field Crops Research. 2016. 196, 389-401. https://doi.org/10.1016/j.fcr.2016.07.018.

Row Cleaners

WHAT IS IT?

Row cleaners, also called residue or trash cleaners, push surface residue to the side of the seeding row to provide a clear path for the gauge wheels. They are usually the frontmost attachment on the planter, although they are sometimes preceded by coulters, which cut residue to prevent dragging.

Properly adjusted row cleaners should push residue just slightly off the center of the row (not onto the neighboring row) and should only move surface residue (not soil). Potential benefits of using a row cleaner include:

- Preventing seed furrow discs from clogging with residue.

- Improving seed depth uniformity, given that a clear path allows for the gauge wheels to run directly on top of (or closer to) the soil surface.

- Improving seed-to-soil contact, given that less residue on the seeding row minimizes the amount of residue that is buried by the furrow disc and can get hair pinned against the seed.

- Increasing soil temperature in the seeding row in the days following planting.

WHAT IS AVAILABLE?

A few examples of row cleaner manufacturers include Yetter, Martin-Till, Precision Planting, Dawn, and Sunco. Most products consist of a pair of wheels that are set at an angle to push residue away. Single wheel models are available for narrow row spacings, in which case it is recommended that half of the wheels on the planter are set to one angle and the other half to another angle (right- or left-handed) to avoid draft. Combinations of row cleaners and coulters are also available. While there is wide variation across models and brands, row cleaners can often be distinguished by:

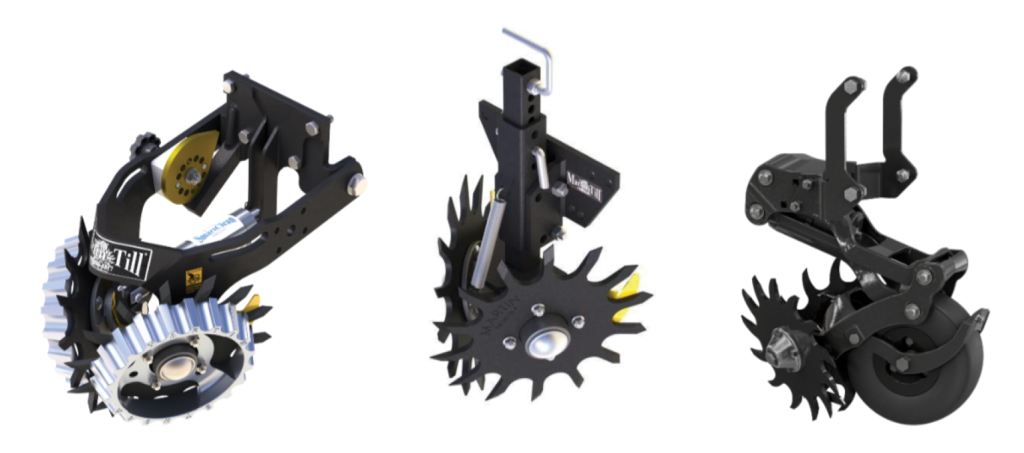

Wheel type: The most common wheels have either sharp or beveled teeth (Figure 7), the former being more aggressive in removing residue and sometimes promoting slight tillage of the seedbed, which may or may not be desired. Wheels can also have a threaded attachment intended to help push the residue further away from the seedbed.

Figure 7. A sharp (left) and a beveled (middle) wheel by Yetter. Wheel containing a treader attachment by Yetter (right). Image source: https://www.yetterco.com/products/0-view-product/206-sharktooth-wheel; https:// www.yetterco.com/products/0-view-product/342- beveled-wheel; https://www.yetterco.com/products/11-plantermount-row-cleaners/308-2967029097-shortfloating-row-cleaner.

Mount type: Row cleaners can be floating or fixed mounted to the planter (Figure 8). Floating types allow for vertical movement beyond the pre-set height to float or follow changes in soil contour. Fixed-mounted types are constricted to the height set for each operation and may require more frequent manual adjustments when moving across different field conditions. A recent release by Precision Planting (Reveal, Figure 8) has its own gauge wheel located just behind the row cleaner, which allows the row cleaner’s height to be controlled by the cleaned seedbed.

Figure 8. A floating (left) and a fixed mounted (middle) row cleaner by Martin-Till, and the Reveal model by Precision Planting (right). Image source: https://store.martintill.com/ bkc1360/; https://store.martintill.com/b1332-772/.

Mount placement: Row cleaners are often mounted either to the row unit or to the planter toolbar (Figure 9). Toolbar-mounted models are claimed to be superior because any vibration experienced by the row cleaner is not transferred to the row unit, which could affect the row unit’s down pressure and general performance.

Figure 9. A row unit (left) and a frame (right) mounted row cleaner by Dawn. Planter toolbar is depicted in white. Image source: http://www.dawnequipment. com/product/4010/; http://www.dawnequipment.com/ product/gfx-h.

Adjustment type: With traditional models, row cleaner height is set manually. With newer models, it is possible to adjust height remotely from the cab via hydraulic or pneumatic control systems (Figure 10).

CAVEATS TO THE TECHNOLOGY

Row cleaners are best suited to high residue conditions, especially at high (>8 mph) planting speeds. If the residue is wet, row cleaners may not effectively clear the seedbed. Problems can also arise from some types of cover crop residues that can wrap around the row cleaner wheels.

It is crucial to properly adjust row cleaners. If they are too shallow, they will not remove residue, and if they are too deep, they will dig a trench which may translate into shallow seeding and uncovered seeds. This is especially important when using aggressive wheels that do not provide any flexibility or automation in height (i.e., sharp-tooth, fixed-mounted, manual types). That said, when field conditions are variable, there may not be an appropriate way to adjust fixed, manual row cleaners.

ROW CLEANER EFFECTS ON SOYBEAN

Studies on the effect of row cleaners on soybean growth and yield are lacking. In corn studies, the use of row cleaners almost always increased seed emergence rate, but that didn’t always result in a higher plant population at harvest or yield (Fallahi and Raufat, 2008; Janovicek et al., 1997; Vetsch et al., 2000). Yield responses were generally observed in poorly drained soils and in years with cool and wet springs, likely a result of soil warming. In a threeyear soybean study in Iowa, row cleaners increased the emergence rate in one of three years, but no differences in yield were observed (Kaspar and Erbach, 1998). Because soybean plants are much better than corn at compensating for suboptimal stands, the value of using row cleaners to reduce the risk of suboptimal populations is likely lower in soybeans than corn. That said, as many producers are moving toward lower seeding rates, percent emergence is becoming more important in soybeans.

CITATIONS:

Vetsh, J.A., & Randall, G.W. Enhancing no-tillage systems for corn with starter fertilizers, row cleaners, and nitrogen placement methods. Agronomy Journal. 2000. 92, 309-315. https://doi.org/10.2134/ agronj2000.922309x.

Fallahi, S, & Raufat, M.H. Row-crop planter attachments in a conservation tillage system: a comparative study. Soil and Tillage Research. 2008. 98, 27-34. https://doi.org/10.1016/j.still.2007.10.005.

Janovicek, K.J.,Vyn, T.J, & Voroney, R.P. No-till corn response to crop rotation and in-row residue placement. Agronomy Journal. 1997. 89, 588-596. https://doi.org/10.2134/agronj1997.00021962008900 040009x.

Kaspar, T.C., & Erbach, D.C. Improving stand establishment in no-till with residue-clearing planter attachments. Transactions of the ASAE. 1998. 41, 301- 306.

Planter Closing Wheels

WHAT IS IT?

Closing wheels are the last attachment on the planter designed to close the furrow once the seed has been placed in the furrow. Proper closure of the seed furrow is essential for improving seed-tosoil contact and more consistent germination and emergence.

The most common closing wheel setup on row-crop planters is two solid rubber wheels, which close the seed furrow slot by pressing the soil closed (Figure 11). However, factors such as soil type, moisture conditions at planting, and tillage practices (e.g., surface residue) can adversely affect the performance of closing wheels. For instance, high residue from previous crops or cover crops can lead to poor furrow closing and inadequate seed-to-soil contact that often result in reduced plant stands and/or delayed emergence. Planting into wet soils or “mudding in” can also increase the risk for sidewall compaction and poor root development, especially if the weather turns hot and dry after planting. Reduced plant stand, delayed emergence, and restricted root growth will negatively impact yield.

WHAT IS AVAILABLE?

After-market closing wheels with protruding fingers or spikes have been developed to improve seedbed conditions in no-till fields with high residue or following cover crops, and fine-textured soils that are more susceptible to sidewall compaction, especially when the soil is wet. Closing wheel manufacturers include but are not limited to, Dawn, Exapta, MartinTill, May Wes, Precision Planting, Schaffert, Schlagel, and Yetter. Spading or spiked closing wheels are designed to crumble/break sidewalls and loosen the soil directly above the seed to facilitate emergence and root growth; the degree of aggressiveness will vary depending on wheel types and models. In general, closing wheels with short or curved spikes are less aggressive than those with long straight spikes. Figure 12 shows an example of after-market closing wheel types with varying aggressiveness. It is possible to ‘mix-and-match’ closing wheel types, such as running a spiked wheel with a standard rubber wheel (Figure 12). These systems may allow for adequate furrow closure under more variable conditions, essentially attempting to get the best of both systems by limiting sidewall compaction while also providing adequate seed-to-soil contact.

CLOSING WHEEL EFFECT ON SOYBEANS

While after-market closing wheels are being widely promoted to improve seedbed conditions, little to no peer-reviewed study has evaluated their effectiveness on soybean growth and yield. Previous studies on corn have shown that after-market closing wheels had no impact on final plant stands in both conventional and no-tillage systems in Iowa (Hanna et al., 2015), but increased corn emergence by 2% under no-till conditions in Wisconsin (Drewry et al., 2020). Another study in cotton found that closing wheel type did not affect seed emergence 10 days after planting (Way et al., 2018).

CAVEATS TO THE TECHNOLOGY

Although after-market closing wheels are best suited to no-till fields, there are some important caveats to this technology. First, the degree of aggressiveness is also associated with soil texture and moisture conditions at the time of planting, so proper selection and setup can vary both between and within fields. If the closing wheels are too aggressive, the spiked wheels can flip the seed out of the furrow. Aggressive closing wheel setups may change the effective seed depth by creating a furrow on top of the seed row or by digging up seed in the trench.

CITATIONS:

Drewry, J.L., Luck, B.D., & Arriaga, F.J. Impact of planter closing wheels on corn emergence in notill systems. Applied Engineering in Agriculture. 2020. 36(5), 727-732. https://doi.org/10.13031/aea.13957.

Hanna, H.M., Schweitzer, D.D., & Licht, M. Tractor and planter adjustments to improve profitability. Proc. 27th Annual Integrated Crop Management Conf. 2015. (pp. 195-205). Iowa State University, Ames, IA. https://doi.org/10.31274/icm-180809-193.

Way, T.R., Kornecki, T.S., & Tewolde, H. Planter closing wheel effects on cotton emergence in a conservation tillage system. Applied Engineering in Agriculture. 2018. 34(1), 177-186. https://doi.org/10.13031/aea.12256.

Authors: Jenny Carleo, North Carolina State University; Daniela Carrijo, Pennsylvania State University; Shaun Casteel, Purdue University; Shawn P. Conley, University of Wisconsin, Madison; Eros Francisco, Auburn University; David Holshouser ,Virginia Tech University; Hans Kandel, North Dakota State University; Jonathan Kleinjan, South Dakota State University; Chad Lee, University of Kentucky; Mark Licht, Iowa State University; Laura Lindsey, The Ohio State University; Emma Grace Matcham, University of Florida; David Moseley, Louisiana State University; Mike Mulvaney, Mississippi State University; Seth Naeve, University of Minnesota; Emerson Nafziger, University of Illinois; Michael Plumblee, Clemson University; Giovani Preza Fontes, University of Illinois; Jeremy Ross, University of Arkansas; Maninder “Manni” Singh, Michigan State University; Rachel Vann, North Carolina State University.